Hot-dip galvanising is the process of immersion of steel fabricated components in molten zinc/alloy. One of the advantages of hot-dipping is that the coatings are much thicker and therefore much more corrosion resistant. Zinc coatings prevent the oxidation of the protected metal by forming a barrier. This is a thick, tough metallic zinc envelope, which covers the steel surface and seals it extremely well from the corrosive action of harsh Australian environments, especially within coastal areas.

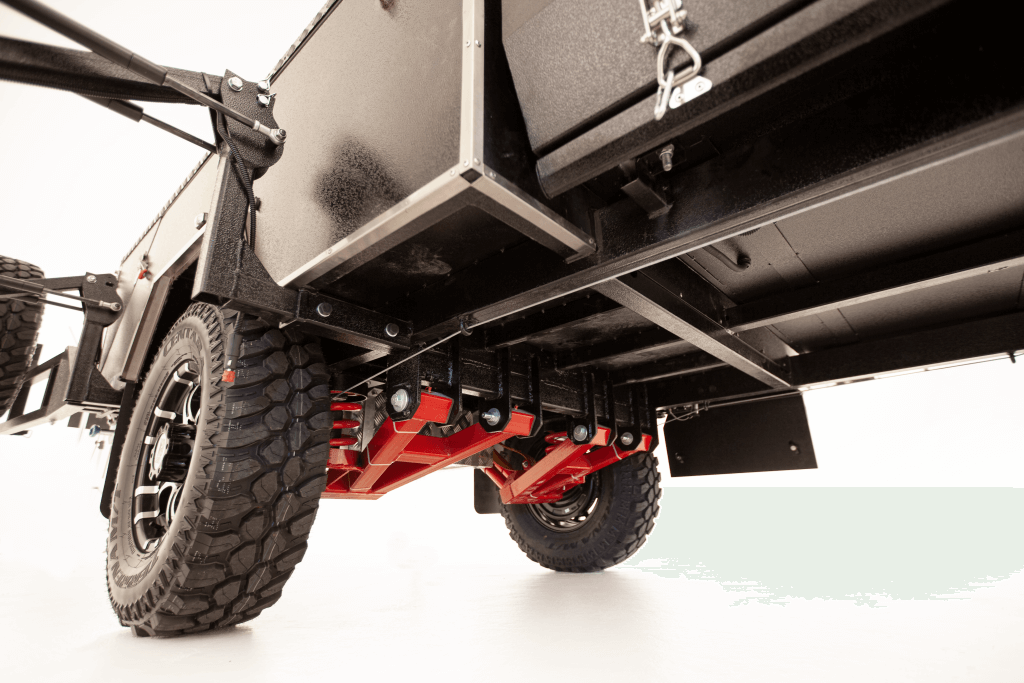

The thickness of a hot-dip galvanised coating is beneficial in providing long life, durability and performance. At Mars Campers, we favour hot-dip galvanising because of the extended maintenance-free service that it provides in protecting the trailer against corrosion. When compared to painting, hot-dip galvanising has similar initial application costs but almost always, lower life-cycle costs, thus making galvanising the smart choice for today and tomorrow. It is the best choice in terms of long term durability and cost-effectiveness.

When going off-road, you are bound to get scratches. Paint is a barrier protector only, and when scratches and cracks occur, corrosion of the underlying steel is immediate. Paint systems require a lot of maintenance, partial repainting and full repainting several times. Over a 30-75 years life, the costs can be staggering, making the decision to paint models over galvanised ones could be a costly one in the long run.