Wheels falling off camper trailers, wheel studs breaking and wheel nuts loosening are very rare, but still occasionally happen to some unfortunate campers out there.

We compiled a list of possible causes so you can learn why it may happen and how to prevent it. This is good to know information regardless of the age or brand of camper trailer or caravan you own.

Check this video to see what vibration can do to the suspension and wheel nuts:

The thread of a screw fastening is spiral and some side clearance must exist to enable the nut (or stud) to be turned. Tightening however causes the stud to stretch slightly. This marginally decreases its diameter, which end up increasing inter-thread clearance.

Inter-thread friction normally prevents or limits sideways movement between the threads but, if any repetitive loads exert sideways force, that force may momentarily overcome that friction. This in turn allows the nut or stud to be thrust slightly from side to side. As the thread is spiral and in tension, momentarily relaxing the frictional contact may cause the fastening to ‘ratchet’ itself undone. This phenomenon is what causes wheels to fall of camper trailers and caravans.

That is what can happen with wheel nuts or studs when the tyre pressures are high on corrugations or the suspension is too rigid for the camper trailer or caravan among other issues. As the wheels encounter bumps and potholes, side shock loads impact the wheel studs. Unless correctly tightened or somehow restrained, the fastenings may work loose.

Jamie from Australian Images explained the effects of corrugation really well in the video below:

This works: Reduce loosening forces by deflating your tyres to around 25Psi while on dirt roads and ensure your camper trailer or caravan are fitted with shock absorbers in a well-suited suspension design.

Loosening mainly occurs where there are repeated side shocks, bending of bolted assemblies, cooling and heating, etc… This could happen particularly with wheel studs and nuts.

Far more wheels fall off caravans and camper do trailers than from cars, but no one is immune to it, yet some camper trailer makers still deny there’s anything about their products that could be improved!

By the way, it can happen on blacktop too.

It does not affect all camper trailers: but mostly those with over-rated leaf springs and no shock absorbers. In areas where most roads are deeply corrugated dirt, there are innumerable wrecked trailers and caravans with wheels torn away (or stub axles broken). Almost all not just lack shock absorbers – they had no provision for fitting them. I guess the message here is clear, steer away from campers trailers and caravans that do not have shock absorbers.

When an undamped wheel (high tyre pressure and no shock absorbers) encounters corrugation or ongoing bumps, it is thrust upward. This compresses the spring. Inter-leaf friction absorbs a small part of the impact energy on the upward movement, but most are retained (as elastic energy) in that spring. Once over the bump, the now unrestrained spring jackhammer the wheel assembly downward. The force is proportional to its mass and the square of its velocity. It strikes the road with huge force – transmitting the shock to the wheel studs and nuts.

Just one crossing of the 800 km or so of the corrugated section of the Tanami track (at roughly 900 corrugations/kilometre) imparts over one million hammer-like blows via those studs. Once a nut or stud works even slightly loose, further shock loads may cause it to fall.

Generally, though, others too work slightly loose and the impact forces shear the studs in half. Such repeated shock loads also wreck wheel bearings, and may eventually cause axles to break and crack the odd chassis in poorly made campers and or vehicles.

By adding yet further elasticity, spring washers make matters worse.

Nyloc nuts add friction and limit sideways movement but in more extreme cases they too may work loose.

Castellated nuts and split pins prevent nut movement but accurate re-torquing is not feasible unless new holes are drilled each time.

Double nuts however work well because the upper one is not subject to sideways loosening.

Left-hand thread nuts (on left-hand wheels) were used at one time on the assumption that anything they strike whilst the wheel is turning tightens rather than loosens them. This does not however restrain from loosening as above. Once the main causes of fastenings working loose became understood, most vehicle makers used conventional right-hand threads on both sides.

Much as firing a gun into water, shock absorbers absorb and dissipate bound and rebound energy. Once that’s understood, the need for shock absorbers seems obvious yet many camper trailers and caravans have springs so stiff there’s little movement to dampen. This also results in trailer contents taking a beating, causing wheel studs and stub axles even more likely to shear.

You may encounter $80,000 caravans with suspension identical to that of box trailers used to cart garbage to the local tip. If a camper trailer or caravan maker says shock absorbers are not needed you are better off politely walking away.

Coil springs have next to zero self-damping and are never used without shock absorbers. Air bags must also be damped.

Rattle guns are prone to over tightening, thereby stretching the stud. This reduces its diameter and increases inter-thread spacing. That alone can cause studs to crack and/or sheer off. The final tightening may only be done via a high-quality torque wrench of known accuracy, and to the vehicle manufacturer’s specified amount. (Mars Campers recommends between 125NM and 135NM across its range of camper trailers and caravans)

They must be rechecked and re-tightened, if necessary, after the first 50-100 km driven, and again after 1000 km. I also pays off to check when enduring long sections of corrugations. Keep in mind that many tyre fitters ‘know better’ and use only rattle guns.

If a lubricant is used (most experts recommend against it) the tightening torque must be reduced by about 20%. Anti-seize materials must never be used for any but totally static applications. This is because their intended role is to ease undoing.

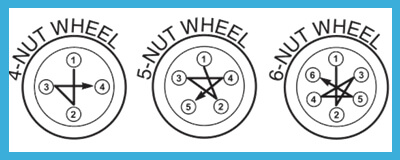

To ensure your camper trailer won’t have wheels falling off, after a tyre replacement follow this sequence:

If having a tyre fitter change wheels, insist beforehand that a torque wrench be used once the fastening is finger tight. Never allow a ‘rattle gun’ to be used for final tightening as there is a serious risk of over-tightening. Ideally, have a high-quality torque wrench and do the final tightening yourself.

If there is no inter-thread gap, no side movement is possible, and hence little likelihood of threaded fastenings undoing. Thus, rather than ‘glueing’ threads together, Loctite (and similar products) expand to fill the gap between threads, thus precluding the sideways movement that enables or causes the undoing.

The specialised Loctite 290 product is designed for fastenings that subsequent re-tightening (e.g. wheel and U-bolt nuts). It is applied after the initial re-tightening period. It is a self-wicking fluid that works its way between even horizontal threads. As the product effectively precludes nut unwinding, further torque checks are (claimed to be) unnecessary. It must be reapplied after wheel changes. (The product is also used for critical applications such as in aircraft, and also roller coasters to prevent loosening of fastenings that is likely to result in catastrophic failure).

At Mars Campers we work hard to develop the best value for money camper trailers with a view of helping you create memorable experiences with your loved ones.

Did you find this information useful and know anyone with a camper or caravan? If you found even one tiny nugget in this material to be useful, please do forward it to three of your friends. I am sure they will thank you for it. You can send it to them via email, Twitter, Facebook or post it on your own website.